With a focus on safety, environmental protection, and innovation, Calucem will remain at the top of the global CAC manufacturers

Yuri Bouwhuis is the CEO of Calucem since 2018. Originally Dutch, the first man of Calucem in the last 20 years held different executive positions in the chemical industry in different countries – China, Singapore, USA, Germany, UK, and finally Croatia. He has great experience in board positions and in international business. The main areas where he worked covered marketing, sales, business development, product development, R&D, and strategy. His rich experience is the result of working in many global companies and different business sectors especially through the last period when he worked in “blue chip” companies.

You came to Pula in May 2018 and took over the leadership of Calucem. What were your first observations and impressions when you arrived at the Pula cement factory with a tradition of production longer than nine decades?

– I was impressed with the Calucem employees and their commitment to and their passion for the company. It is not uncommon in Calucem to have worked with us for more than 20 years. Furthermore, I was impressed by how long Calucem has been active in the market and how the company over the decades has evolved into a global company. Last I noticed was that the Cement Factory is completely integrated into the city center as well as the neighborhood and the local community.

The factory this year celebrates the 95 years of its establishment. How has cement production developed on the St. Peter peninsula, in other words how has it evolved to what Calucem represents today?

– The company has advanced further under the 4 C strategy. Calucem added sales into new Countries and explored even into new Continents. In comparison to when I joined the company in 2017, we have doubled our Product Concepts to the market and have expanded and added new Customers. Last but not least we have increased our Communication both internally as well as externally.

Calucem is the only Croatian and one of the world’s leaders in the production of alumina cement. What kind of cement is that and what’s its purpose?

– Our Cement is a specialty cement and is in reality closer to a Specialty Chemical then to other cements. The „CAC“(Calcium Alumina Cement) is sold in a wide range of applications: predominantly in Building Chemistry, Refractory as well as numerous specialty applications. The CAC main product characteristics are fast setting, quick hardening and it works well within an abrasive environment. The origin of why Calucem is in Croatia has to do with the fact that all the necessary raw materials were available locally in Croatia.

How does the production process of alumina cement production flow looks like, from the supply of raw materials to the finished product, and what are its specifics in relation to the production of other let’s call them regular types of cement?

– The process Calucem uses for production is a more complex process of melting raw materials, whereas the more common process for making cement is via sintering. During the melting process, a chemical reaction takes place in a kiln. Large pieces of product come out of the kiln, which we call clinker. The clinker gets ground and blended via a specialized and innovative process according to the cement specification.

You are a significant global manufacturer of a special and high-quality product, and usually for special and high-quality product is easy to find their customers. Where on the globe all your customers are placed?

– Currently, we are operating in 67 countries. We have a complex and adaptive logistic system to bring the product close to our customers and we operate several warehouses in different regions to ensure security of supply.

Can you please explain how, and how much the corona crisis affected the operations of your key business partners and how this will affect and reflect, according to your predictions, on the business of Calucem?

– Like every other business in the world, we have felt the impact of the Coronavirus. I am very happy to be able to confirm that till date none of our colleagues in Calucem have been infected by the virus. There have been many challenges and we have asked a lot from our colleagues to enable us to continue to produce, supply, and sell: skeleton crews, working from home, no face to face meetings, no travel, etc. There has not been one single disruption in the supply to our customers during the COVID time, which is quite an achievement given all the country lockdowns and restrictions that were in place and are now partially being reinstalled due to 2nd wave infections in different countries.

In many jobs, there is no progress without continuous investment, both in progress and modern technology and in people. What are the priorities according to that, and which are the most significant investments in Calucem in past few years?

– Calucem has recently completed a very large investment of 22 Mio Kuna (or 3 Million Euro) in Pula. The Briquetting Plant contributes to reducing CO2, developing a circular economy, and giving an additional boost to more ecological and greener production. Furthermore, the plant significantly reduced potential noise and dust issues in Pula as well throughout the Istrian peninsula.

Maintaining the highest level of all prescribed environmental standards is certainly not an easy task for any factory located in an urban environment. But Calucem has been going for a long time and he has been a “neat and clean” neighbour to the residents of Stoja for a long time. I suppose that requires a lot of effort, constant monitoring, and significant investment?

– Compliance with the local legislation is essential to run our business, but we strive for much more and are continuously searching for ways to reduce waste, noise, and any further impact we may have on the environment. We are in constant contact with our neighbours as well as the local authorities and take any complaint very seriously. This includes the impact on our employees and any visitors, as safety comes first in our plant.

Another important obligation in a complex production process such as yours is the safety and health of the workers. Do you have any special measures and activities in Calucem that make that obligation never slip out of focus?

– We have a complex system of ensuring the health and safety of our employees. There are several procedures in place that have to be followed, including PPE (Personal Protection Equipment) that must be worn at all times in the plant. Our employees go through extensive training and we have recently installed a new department called ESHQ: (Environmental Safety Health and Quality) to safeguard that we remain focused on these very important topics. For instance, we hold announced and unannounced audits to determine any new arising issues. Furthermore, we pride ourselves that we recently celebrated our first 365 days of NO accidents.

How many employees Calucem employs directly in the factory and sales offices around the world, and how much through a branched network of subcontractors and in what industries/activities?

– Globally we are currently around 200 Calucem Employees, which includes all legal entities in the USA, Germany, Croatia, and Singapore.

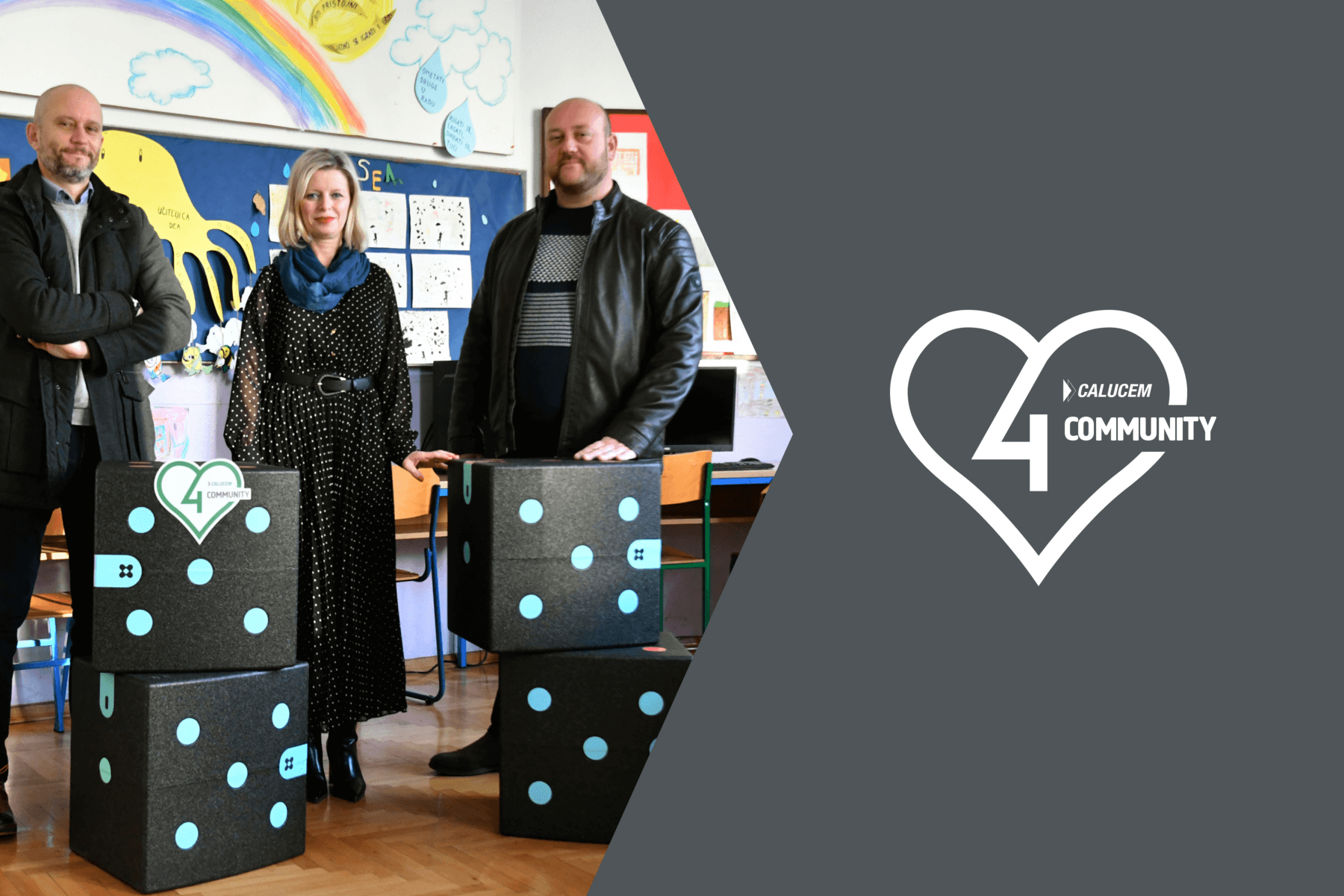

Calucem has repeatedly confirmed itself through numerous donations as a socially responsible partner of the local community, and the backbone of everything is your program “Love for Community”. To whom is this program targeted and what is its main goal?

– Our “Love for Community” program is in its 10th consecutive year. It is intended to give something back to the community in Istria and Croatia, which I and my colleagues fully support. The program donates to a wide array of institutions ranging from schools, educational institutions, sports clubs, cultural and charitable institutions.

For the end a few sentences on the future and plans. 95 years is behind you, what is your vision for the future of the development of the factory and continuity of the rich Pula tradition of cement production?

– Despite the recent challenges, I see a bright future for Calucem to continue to build on its history in Pula. We have and are continuing to invest in Pula in new technology, people as well as working on new generations of products, that are for instance dealing with the reduction of CO2 emissions within the value chain, as well as directly in our products.