95 years of the Cement factory on Pula’s peninsula St. Petar

Calucem, the company’s name since 2006, is well established in the global market of calcium aluminate cement. The factory, which today employs around 160 employees and numerous subcontractors, is one of the world largest producers of calcium aluminate cement, exporting to more than 60 countries around the world.

PULA – In 1925, recovering from the Great War the industrial production was slowly reviving. Pula, the largest war port of the Austro-Hungarian Monarchy, is now part of the Kingdom of Italy, so new facilities are beginning to develop in the Bay of Pula, which are no longer directly related to the military industry. The Italian government invited entrepreneur and engineer Emilio Stock to design and launch an initiative to start a cement production in the area. Not coincidentally, because this enterprising citizen of Split has already proven to be very successful in these matters, and from the beginning of the twentieth century he founded two cement factories near Solin, and the first factory of asbestos-cement products Salonit in Vranjic just before coming to Pula. His engagement in Pula also proved successful, because in 1925, with 10 million lira of capital to build the factory, the Sociate Istriana dei Cementi was founded on the premises of the Pula Arsenal, thus beginning the history of the Pula cement factory.

Getting started

The newly established company received a fifty-year concession for the use of a set of buildings located on the St. Petar peninsula, and the condition was that 500 workers would be employed in the new factory. The Pula cement factory began working on October 1926. With further development and investment in technology, the factory had better production capacities, and a new rotary kiln with a production capacity of 1500 quintals of cement per day was inaugurated on October 1932. Although it has been producing calcium aluminate cement and ordinary Portland cement since its foundation, and white Portland cement since 1932, the factory has been producing only special calcium aluminate cement since 1997. Unfortunately, the Pula cement factory experienced the full impact of the second world war as the factory was the target of Allied bombing on several occasions. The factory facilities were hit and damaged several times during these bombings, and after the war, the reconstruction followed that lasted until 1950 when it was given to the employees to manage. After the war, the factory was given a new name. Giulio Revelante was employed at the factory from December 1933 as a manual worker on a briquette press. At that time, the factory employed as many as 750 workers, which was the highest in its entire history. After the war broke out, Revelante joined the partisan movement, and in 1943 he died in his native Pazin region. In memory of his sacrifice, the factory took his name in 1949, and on the occasion of the 60th anniversary of its existence, a buste was placed in front of the factory entrance, which was recently moved to Tito’s Park on Pula’s Riva. The growth continued after the war and the Pula cement factory reached an all-time record volume of calcium aluminate and white cement produced

A new page in history

In 1963, the factory merged with the Koromačno cement factory and the lime factory in Most Raša, in then SOUR, was called the Istrian cement and hydrated lime factory. The production capacities were modernized in 1977 with the construction of a new line of white Portland cement. A new page in history turns after the independence of Croatia. In 1993, the factory went through the privatization process and came into majority ownership of the German group Heidelberg Zement, changing its name to Istra Cement International, and then in 2002 it was renamed Istra cement. The new owner abolished the white cement production line in 1997, but significantly modernized the calcium aluminate cement production line. The main product characteristics of the Pula calcium aluminate cement are the resistance in an abrasive environment and the speed of setting which is why the product is in great demand on the world market, specifically in the building chemistry industry. The company was renamed to Calucem in 2006 when there was a Management Buyout and the company went into ownership of Private Equity.

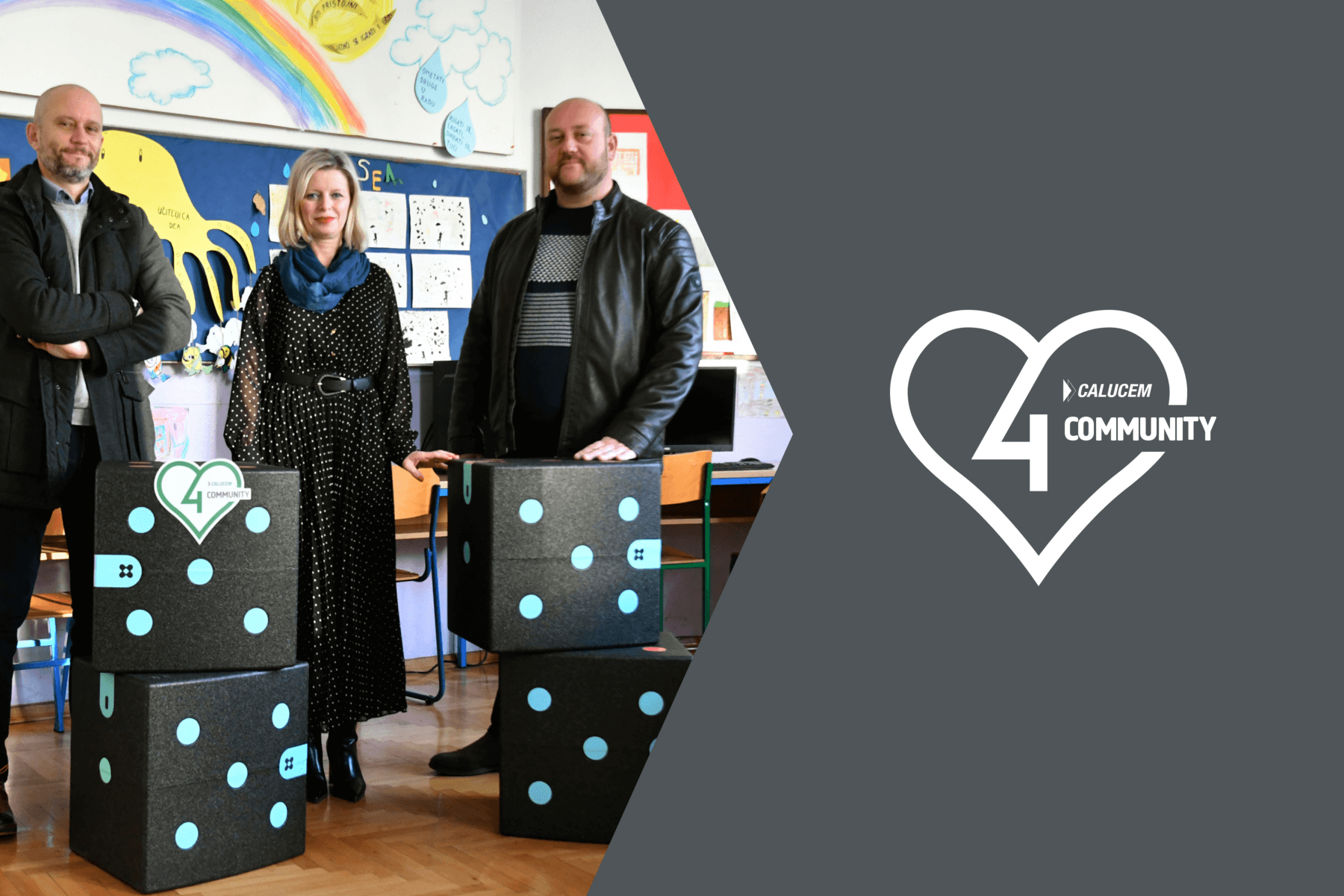

Corporate social responsibility

The factory, which today employs around 160 employees and numerous subcontractors, is the world’s largest production site of calcium aluminate cement and its derivatives. The company has been exporting products to more than 60 countries around the world for many years. The main markets are in the European and NAFTA region, but cement produced in Pula can also be found in the outer corners of the Asia Pacific region. Through a series of significant investments in the technology, the environment, and infrastructure of the factory, as well as in the health and safety of employees at work, Calucem has long been recognized as a serious business entity operating according to the principles of corporate social responsibility. This is evidenced by the program titled “Love for Community”, which supports various sponsorships and donations to health, educational and cultural institutions in the city and region. In that same spirit to commemorate its 95th year anniversary the cement factory instead of celebrating its anniversary and due to the COVID-19 pandemic, has decided to reserve this money and make a donation instead to the General Hospital Pula which will use this donation to purchase a VisiClear device for the central operating block in the new hospital, to help to combat against COVID-19.

St. Petar peninsula was one of Pula’s islands until 1862. It is mentioned among the islands of Bay of Pula by the Italian Renaissance geographer, physician and writer Giuseppe Rosaccio in his isolator (Viaggio da Venetia a Costantinopoli). According to some sources, a church was built on the island during the 6th century, and it is assumed that it was named after it. Spreading K.u.K. war ports and the construction of the Arsenal in the nineteenth century buried all the shallows of the intended bay of Pula to the island of Petar, which in those years was connected to the mainland and became a peninsula.

Today, Calucem produces a wide array of different calcium aluminate cement in Pula Products within the product group additionally differ in mineral composition and fineness of grinding. The alumina content gives our calcium aluminate cement exceptional properties of resistance to high temperatures, acids, as well as the rapid achievement of high strength. For these reasons, calcium aluminate cement from Pula is used in very demanding applications such as sewer systems, but also in adhesives for ceramic tiles as well as in the construction of building partitions and numerous other applications.

On behalf of General Hospital Pula, I would like to thank you for your valuable donation that will be used to purchase a device for smoke and aerosol evacuation, which are created during surgical procedures.

In these, certainly increasingly difficult times, every action and donation contributes significantly to better and safe work when performing surgical procedures.

I would like to emphasize the excellent cooperation with all your company in the realization of this donation.

With respect,

Ivica Fedel dr.med.

Deputy Hospital Director of General Hospital Pula